Our services

Our

Services

Precision in any cutting technique – Efficient. Versatile. High quality.

- 01

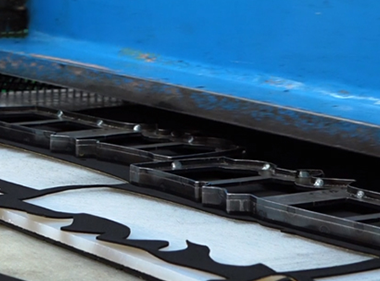

Precise punching for versatile materials

Thanks to our modern machinery We are able to process a wide range of materials with the highest precision - always individually tailored to your requirements. Standing Efficiency and quality equally in focus in order to offer you economical and first-class solutions.

For each type of material, we rely on the appropriate process: In addition to classical punching techniques We also use it if necessary. waterjet cutting, Laser cutting or CNC cutter, to precisely realize even demanding shapes and complex contours.

With our many years of experience and a flexible manufacturing process, we ensure that your projects on time and in the highest quality implemented.

- 02

columns

In many applications, the precise processing with minimal tolerances decisive for the quality of the final product. Exact material separation not only ensures optimum results, but also facilitates all subsequent processing steps.

Thanks to our many years of experience in the processing of EPDM, PE and alternative foams We guarantee millimeter-precise cuts with highest repeatability. Our state-of-the-art processes allow for efficient and economical processing, which is exactly tailored to your requirements.

With our know-how and advanced technologies, we ensure that your materials are perfect quality ready for further use.

- 03

Laminating/gluing/multilayer

Whether for functional or aesthetic requirements - we offer precise coating, bonding and laminating solutions, which are exactly matched to your specifications. Through the targeted use of modern Laminating and Adhesive Techniques we combine different materials into high-quality multi-layer composites (Multilayer), which meet the highest requirements for stability, durability and functionality.

Our procedures ensure an uniform and long-lasting adhesion, regardless of material or surface structure. We rely on individual solutions, which optimize both the mechanical and optical properties of your products.

With our experience and technological know-how, we ensure that your materials are processed exactly to specification - reliably, efficiently and in consistently high quality.

- 04

Water jet tailor

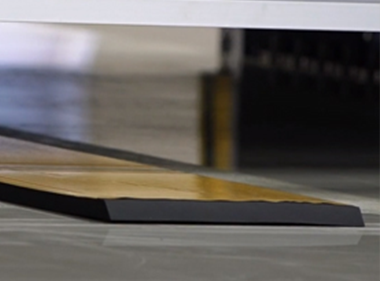

For thicker materials, our state-of-the-art waterjet cutter the optimal solution to produce precisely and neatly formed parts – without the typical deformations of conventional stamping processes.

While conventional punching deforms the material by printing and thereby concave edges Leave it behind, make it possible abrasive waterjet cutting one exact, straight cut, even at high material thicknesses. This process protects the material, prevents undesirable deformations and ensures highest cutting quality.

Since the material comes into contact with water during the cutting process, we recommend using sensitive materials Preliminary test runs, to check water suitability and ensure optimal results.

With our experience and modern technology, we offer you a high-precision, flexible and material-friendly cutting solution for your individual requirements.

- 05

Laser cutting

This Laser cutting is an ideal alternative to the conventional stamping process and offers decisive advantages, especially in plastics and other sensitive materials.

Through the targeted Heat exposure of the laser the cutting edges are not only precisely separated, but at the same time sealed, which prevents fraying or chipping of materials. This makes the process particularly efficient for applications where clean, smooth and closed cut edges are required.

Thanks to our state-of-the-art laser cutting technology, we can even produce complex contours with highest accuracy and repeatability realisation – tailor-made to your individual requirements.

- 06

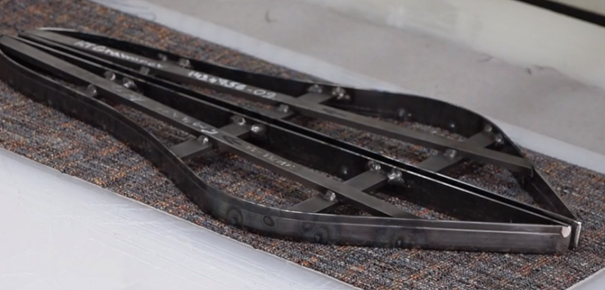

CNC Router

For particularly precise and material-friendly cutting processes, we rely on CNC-controlled Oscillating Knife Cutting. This method is ideal for flexible, soft and multi-layered materials, where traditional cutting methods reach their limits.

Thanks to the High-frequency oscillating blade movement Even sensitive materials such as EPDM, foams, textiles and leather cut with the highest precision – without thermal impact or deformation. Compared to laser cutting or waterjet cutting, this Knife cutting process a particularly clean cutting edge, without the material melting due to heat or being affected by water.

With this state-of-the-art technology, we expand our portfolio and offer tailor-made Cutting solutions for demanding applications, always with a focus on efficiency, quality and material utilization.

Finishing & finishing - perfection down to the last detail

- 07

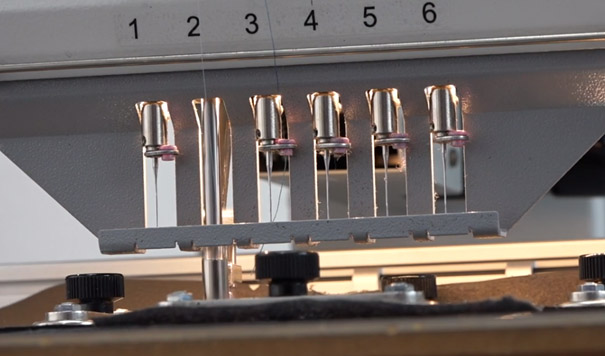

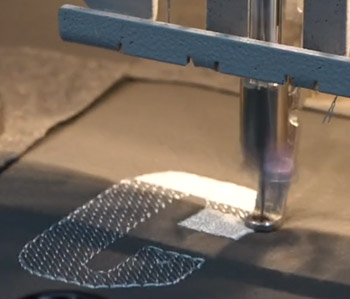

High quality embroidery - for leather & textiles

Our professional embroidery Give your products a exclusive and long-lasting finishing. Whether logos, individual designs or functional markings - we offer high-quality embroidery on leather, technical textiles and fabrics.

Especially with leather requires embroidery special expertise and precision, to ensure a first-class result without material warpage or damage. With our experience and state-of-the-art embroidery technology, we detailed designs with High repeatability and durability Um.

Whether for Automotive interiors, furniture, clothing or technical applications – we adapt to your requirements and deliver tailor-made solutions of the highest quality.

- 08

Set individual accents

Do you want your Leather, textile or upholstered articles with one individual logo design ennoble? We offer you a variety of high-quality design options:

- embroidery – Detailed and durable logos on leather & textiles (More information under "07 – Embroidery")

- Leather embossing – Noble and durable embossing for a high-quality appearance

- Colour printing on textiles – Flexible and colour-intensive design of your products

With these finishing techniques, we give your products a unique and professional brand identity. Let's turn your idea into reality!

- 09

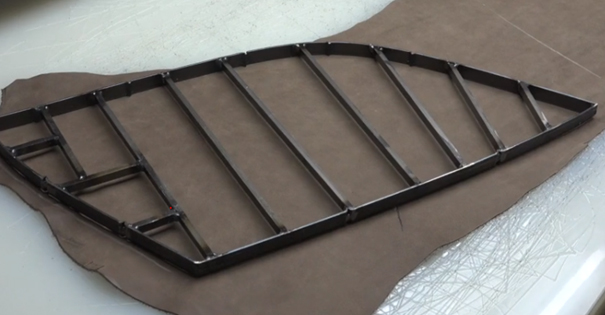

High-quality upholstery

With decades of experience in upholstery We manufacture high-quality seating and upholstery solutions various materials – from fabrics and technical textiles to leather. Particularly in Leather upholstery and complex custom-made products Benefit from our specialized expertise and precise processing.

A special advantage: Everything from a single source. From Raw material via cut and sewn components up to finished upholstered and embroidered end product – all processing steps are in our production only a few 100 meters away from each other. This means for you efficient processes, shorter delivery times and highest quality assurance.

- 10

The seam - High-quality workmanship for demanding projects

Our modern sewing It is another core of our production. With a team of Experienced professionals and one technologically advanced equipment we realize ourselves complex sewing work with the highest precision.

We specialize in high-quality covers for office chairs, upholstery made of leather and fabric as well as custom-made products in small series. Thanks to our precise workmanship, we meet the highest quality standards - from durable seams to sophisticated designs.

In addition, we offer an flexible textile processing for various industries, including Clothing, automotive interiors and interiors. Thanks to our versatility, we implement individual customer requirements efficiently and with the utmost care.